Project Profile

July 2024 Project Profile

Wildfire Defense

We are in the final stages of the new facility for Wildfire Defense. You might recognize this building, as it is right around the corner from our shop. We partnered with Divcon on this project and provided the following scopes. Interior metal stud Framing, Drywall Hanging, Taping, interior painting, exterior painting, and interior decorative acrylic plaster finish. We demonstrated the variety of scopes we can perform, even some of the specialty scopes. Wildfire Defense is the largest wildfire-responsive service in the nation. Their service encompasses 22 states across the County. Wildfire Defense fights active wildfires, monitors active wildfires from their facility in Bozeman, and provides consulting services for wildfire risk to commercial properties. Some of you might know that there was some excitement when the roof of the building caught on fire early on in the project. Minimal damage was done, and we could proceed after a slight delay. We are in the final stages of this project, wrapping up the interior punch list and the exterior painting of the building. Thank you to the All Wall employees who worked on this project and made it a success!

-Cody Luttrull

June 2024 Project Profile

Grand Coulee Fire Station

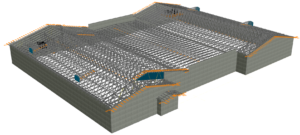

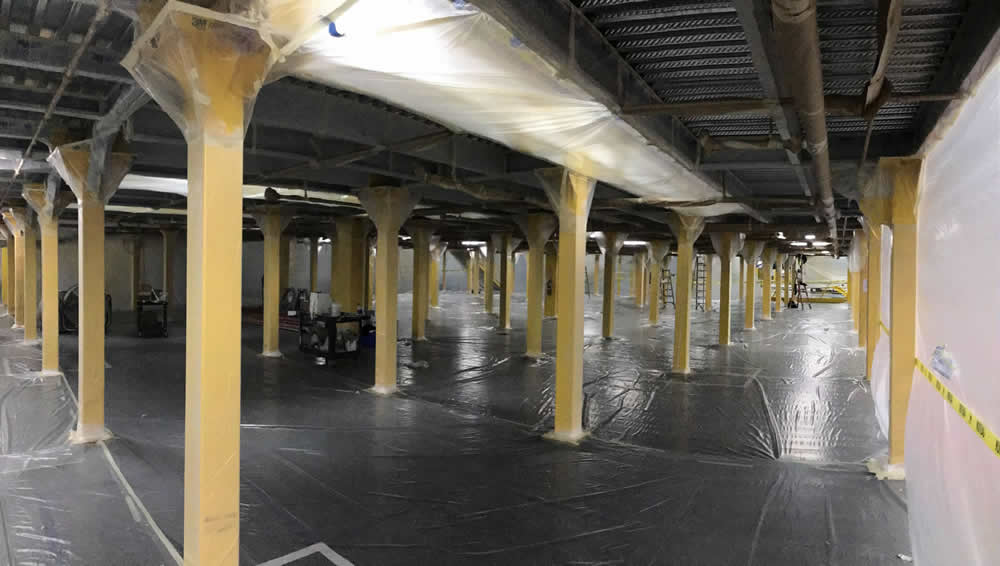

What could go wrong with a partially started building that has sat for years? Back in 2022, AWC had an opportunity to partner with NNAC on the Grand Coulee Dam Fire Station. As we discussed this project as a team, we knew there would be challenges. What was started? What materials were on site? How long would we be there? We asked ourselves these questions. But with all that in mind, we knew we couldn’t miss out on this one.

Before NNAC took over this project, it was a raw shell with some framing completed. Not knowing what lay ahead, we dug into what would be this 22,000 SF 2-story facility. This project let us show how talented the AWC team is. When you think AWC, you think frame, hang, tape, and paint. After the Grand Coulee Dam Fire Station and the great work from Johnny Drywater and Phil Evans, you will now add wall fixtures and ceilings to our list of skill sets. This facility boasts metal ceilings, wood ceilings, and wall features. The precision and accuracy of the AWC team were spot on. I want to personally thank everyone who was involved and took the time to travel out of town to complete this project. Now that the 18-month time frame for this project has finally come to a close, we can enjoy the beautiful craftsmanship of the Grand Coulee Dam Fire Station. Thank you, NNAC, for the partnership and teamwork! We look forward to the next one.

-Caleb Bradbury

May 2024 Project Profile

Spokane Step Phase 3

All Wall has had the honor of working with Swinerton Builders for the last 3 years at the Spokane Tribe Casino. First, adding onto their casino with phases 2 and 2B which boasts beautiful ceiling and soffit work that really showcases our framing, hanging, and taping crews’ amazing talent. For the last year, we’ve really had a chance to shine through with the construction of a 5 story, 175 room hotel with lots of great amenities and special features utilizing metal studs that create the bones of this beautiful building. Among those features are 4 meeting rooms, a retail space, and fitness area. All of which contain hundreds of feet of soffits and light coves. The hotel has a large indoor pool that required all of the drywall to have a high end level 5 finish that our tapers did not disappoint on. As with the other phases of the casino, the lobby, lounge, and registration area spotlight our talented framer’s abilities with a significant amounts of tiered radius soffits. After our tapers put the final touches on these, it creates a great first impression for the hotel guests. This project had a very aggressive schedule, and more than a few challenges along the way but as always All Wall was able to provide solutions and lead the way with a can-do attitude and a willingness from our field team to work 6 days a week. I am very proud to have been a part of this project, and thank everyone involved for helping complete another great build that will have a lasting effect for years to come!

-Joshua Menosky

April 2024 Project Profile

Izumi

Izumi Asian Bistro is another successful project from the Team at All Wall Contracting. Baker Construction was the General Contractor and Uptic Studios was the designer. Estimated by Jeff Woody and Scott Silvers. Scott managed the project.

The project was made possible when the owners of this South Hill restaurant decided to expand their current location rather than seeking a new location. After the original building was cleared out, an adjoining space was also cleared out in anticipation of the expansion and then the jointly shared walls were removed.

AWC was tasked with framing, GWB hanging and finishing, painting and ACT work. Shawn Stilson’s framing and hanging crew completed several technically challenging soffits over the bar and entry way, in addition to the entire straight wall that needed to be done. Fred Frolov took on getting this project lined out while facing the difficulties of a small space remodel with a very active owner and other challenges. With framing and hanging completed, Dave Hartman’s team showed up and began to work their magic. Several miles of corner bead and multiple rounds of mud and sanding later, the walls looked fantastic. Eric Garnett and David Williamson began the painting by applying black dryfall to the open ceiling. The walls, doors and frames were then coated in black paint as well. The finish level was immaculate given the known challenges of working with black wall paint. Phil expertly installed ACT in a cramped and occupied kitchen space.

With a few minor paint touch ups and some additional trade damage repairs, we were able to successfully finish our part in this remodel process. The restaurant opened to a packed house and has been full ever since. The finished project is beautiful and a demonstration of the full package capabilities of our All Wall Team.

-Scott Silvers

March 2024 Project Profile

Hayden Surgery Center

Construction of the new Hayden Surgery Center is in the final stages of completion. All Wall had the honor of working with one of our loyal customers Ginno Construction. This project was full of challenges and delays but all in all the final product is top notch. We performed many of the scopes our company offers to push this project to the finish line. Hayden Surgery is a two-story, 26,000-square-foot building. The main floor will include Orthopedic Urgent Care, orthopedic clinic and a physical therapy office. The second floor will have a state-of-the-art outpatient surgery center with four operating rooms and a procedure room. The basement will have storage, mechanical and electrical spaces. I would like to thank all of the All Wall employees who worked on this project from beginning to end.

-Dylan Jackson

February 2024 Project Profile

Ponderay Springhill Suites

The SpringHill Suites by Marriott in Ponderay, ID is almost complete and our work is almost at an end. Dick Anderson contracted us to help them complete this 3-story hotel, which contains 97 guest rooms, two stairwells, a fitness room, a pool/jacuzzi area, and a bar with dining area. Despite the vigorous schedule and numerous obstacles, All Wall Contracting has completed a beautifully professional finish. We were responsible for completing multiple scopes. Starting with framing ceilings and soffits, followed by a great deal of drywall, which we installed and finished. Following directly behind the tapers were our wallcovering installers, who installed vinyl wallcovering in all 97-guest rooms and throughout every corridor on all three floors. Working side by side with our wallcovering installation crews were our talented painters who stained exterior wood and completed all of the interior painting. I would like to give a special thanks to the multiple crew leads we had on site that helped push this project along. Lincoln Larson, Allen Keuhn, Mike Hughes, and Robert Eastwood, we could not have done it without you.

-Isaiah Alexander

January 2024 Project Profile

Kindred & Co Bookstore & Bistro

We are currently wrapping up the final touches on a new Bookstore and Bistro called Kindred and Co. located in Post falls off Idaho Street near the new Millworx development. We are working with Leone and Keeble on this project and have completed the following scopes: interior and exterior metal stud framing, exterior sheathing, drywall hanging, taping, painting, water repellants and wall covering. When finished the building will be half a bookstore and the other half a small bistro. This building has many high-end finishes, from the interior brick walls, multiple radius soffits, one circular soffit at the twelve sided domed skylight, metal stud framed coffered ceiling, exterior radius metal stud framed parapet walls and entry soffit, ten different wall coverings, and a glass conservatory that you sit in and watch the stars. Due to the high-end nature of this project, this building is going to be featured in an architecture design magazine. This is another project that all of us at All Wall have showcased our high quality of work and can turn over a project that the owner and future customers will love. We are down to the final touches on this project and I want to thank all of the All Wall Employees that worked on this project to make it a success!

-Cody Luttrull

December 2023 Project Profile

Mistequa Hotel

Mistequa Hotel in Chewelah, WA is wrapping up and All Wall is racing to the finish line to complete this beautiful project. We built this project with Woodstone, Inc., an out of town GC that knew they could count on us to build this hotel from our past work experience. The hotel boasts 69 rooms, a fitness center, pool and kitchen that All Wall hung drywall, taped, painted and installed the wallcovering and FRP. The 3-story hotel was wood framed and came with the many challenges that wood framed buildings have, but we overcame them. There is a beautiful conference center attached to this hotel where All Wall was able to showcase our skills in metal stud framing and what a difference this type of construction can make on the final product. Our framing at the conference center consisted of the exterior bearing walls that supported the roof joists, a Porte Cochere, interior partitions creating the conference spaces, restrooms, offices and a bar, an arched fireplace, as well as hundreds of feet of stepped soffits and false beams. Our talented team of finishers and painters turned all of this into some great features for the guests of the hotel to enjoy!

-Josh Menosky

November 2023 Project Profile

Montana Sash and Door

Montana Sash and Door is another project contracted through Ginno Construction, with Kyle Wells as the Project Manager for Ginno and Jeremy Hiaasen the project Superintendent. This project, located in Rathdrum, ID, will be the future home of a new door and window supplier in our area.

It is a CMU Building with the interior framing made out of wood so Ginno exclusively contracted us to hang the GWB, tape and paint. The building has an exposed ceiling in the office area, so we installed Zip trim around the entire show room/conference room area and finish to a level 4. All would have been a smooth job, except most of the rough openings were framed wrong, for both the doors and for the windows. We had to go back, remove corner trims, rehang, tape, and paint them. Those who have worked on a project by Jeremy know that he is very particular about finishes. Brian Haskins was the lucky Painter picked to complete this project, and was able to make Jeremy happy despite the challenges with the framing. We applied WB concentrate to the exterior CMU, stained all of the canopy beams and wood framing members, painted the interior of the shop, but not the lid (which had to be kept clean) along with the mezzanine ladder and the safety rails. In the office area, he also painted the restrooms, offices, break room, show room and conference rooms along with the metal doorframes. All in all this project came out looking great and we turned another quality project out.

-Terry Jones

October 2023 Project Profile

Kootenai Electric Co-Op New Headquarters

The construction on the new Kootenai Electric Co-Op is in the final stages of completion. All Wall had the honor of working with Paric Construction to complete this job. We worked diligently to meet the deadline set for the completion of this project. We were able to perform most of the scopes we offer; exterior and interior framing, exterior sheathing, hanging, taping, wallcovering, and interior/exterior painting and staining. This 180,000-sqft facility features indoor and outdoor equipment parking and storage, an electro technician shop, an engineering lab, multiple war rooms, maintenance facility, material storage, lobby, Drive thru and a state-of-the-art training facility. I would like to thank all the All Wall employees who worked on this project from beginning to end. The completion of Kootenai Electric has been a long time coming. It has been a privilege to be a part of a project that will serve the Kootenai community for many years to come.

-Dylan Jackson

August 2023 Project Profile

SFCC Fine Applied Arts Building

All Wall Contracting is proud to be a part of the SFCC Fine Applied Arts Building project, taking charge of the crucial painting and exterior water repellants for Swinerton Construction. Amidst the challenges of a fast-paced schedule and a tight timeframe, our dedicated team of 6-8 professionals has been working tirelessly to ensure the project’s success. With the upcoming school year approaching, we are in a race against time, aiming to complete the project by August 2023.

Under the joint leadership of Dale Phillips and Alex Woracker, the project has thrived with their combined expertise and efficiency. At first glance, the SFCC Fine Applied Arts Building may appear straightforward with the drywall and exposed ceiling painting nearing completion. However, the true mastery of All Wall Contracting’s painters will be revealed when they put the finishing touches on the other intricate elements and substrates that call for a paint finish. Their meticulous attention to detail promises to elevate the project’s aesthetics, leaving an indelible mark on the building’s appearance and ensuring a stunning environment for the students and faculty at SFCC.

-Caleb Bradbury

July 2023 Project Profile

Liberty Lake Residence

We have recently completed the EIFS on this high-end custom residence with a detached indoor Pool house overlooking Liberty Lake. The project site is on the west facing mountain side looking over Liberty Lake and the Spokane Valley. A 500 foot long by 30-foot-tall retaining wall was built and backfilled as the foundation of the buildings. The builder is Goldstar Construction and the owners are retired business owners from northern California. The house was designed to take advantage of the amazing view of the location and exterior was a combination of EIFS, wood and stone.

The owner originally desired a Stucco finish but also wanted a very smooth surface. We proposed an EIFS system with a Sto Freeform Lotusan Acrylic finish to create the smooth look they were seeking. The substrate on which we installed the EIFS was the Huber Zip System, an all-in-one sheathing with continuous insulation and an integrated moisture and air barrier. As the Zip system is relatively new to the market, the STO manufacturer required their STO tape to be applied at all Zip System tape and STO Gold Coat to be installed prior to adhesively fastening the EPS foam. The Zip panel system includes 2” rigid R-9 foam attached to structural sheathing. The interior wall cavity is spray foam insulate and our 1-1/2” EPS over the sheathing, this has created an extremely efficient thermal, water and air resistant envelope.

Our crews installed multiple base coats and multiple finish coats to achieve an extremely smooth finish. The Sto Freeform Lotusan finish is a self-cleaning material that will shed dirt and dust eliminating costly maintenance for the owners. Our plaster crew started the project on November 1st 2022 and worked diligently through the winter finishing in mid- May 2023. They battled winter snow and wind storms with below freezing temperatures, deep snow and treacherous icy roads. There were multiple days when it was not possible t reach the project due to the road conditions. Our plasterer team fought through all the challenges and delivered an impressive project for a very pleased customer. Kudos to all the EIFS crew for another quality job and dedication.

-Roy Glisson

June 2023 Project Profile

Orthopedic Surgery and Sports Medicine

We recently wrapped up the final touches on the new Orthopedic Surgery and Sport Medicine building in Hayden, ID. Some of you might recognize this because it is right down the street from another project we are currently working on. The GC, Williamson Johnson, contracted us to complete the hanging and taping of drywall, interior paint, and exterior paint. The final result was a colorful one. The interior walls have six different colors throughout and a majority of the building has an exposed ceiling that we painted with dryfall.

We completed a majority of the work for this project last winter. The building sat empty for two months waiting on the electrical equipment that was delayed. This pushed back all of the remaining finishes and punch list. We still had the exterior to paint and stain when the weather allowed which worked out perfectly with the interior punch list items.

Ultimately, everyone is very happy with this project. Thank you to all of the All Wall employees that worked on this project to make it a success!

-Cody Luttrull

May 2023 Project Profile

Spokane Valley Senior Housing

All Wall Contracting recently completed the Spokane Valley Senior Housing construction project for Dawson Construction. We were contracted to perform ceiling and soffit framing, hanging, taping and texture, interior and exterior painting, and wallcovering. Despite numerous delays, complications and challenges, the project will be completed in just over one year. All Wall Contracting utilized their expertise to overcome these challenges and turn over a quality project. Multiple crew leads and four Superintendents provided guidance and leadership to push the project to completion. This high-profile senior living facility is a testament to All Wall Contracting’s commitment to quality and expertise in the construction industry.

-Caleb Bradbury

April 2023 Project Profile

Goodwill – West Plains

We are currently close to completing work on a 60,000 SF Goodwill Facility in Airway Heights, WA. This new facility will have a retail and outlet space and is the largest Goodwill facility in the inland northwest. Baker Construction is the GC on this project, and we are preforming almost all of our scopes we offer. From exterior and interior framing, exterior sheathing, hanging, taping, exterior and interior painting, EIFS, and FRP. We still have to complete the exterior painting when the weather allows which is right around the corner. With Goodwill wanting to open the facility in late spring 2023 it will be a big push to the finish line. There were high expectations for our team on this project from both the General Contractor and the Architect. Thankfully, everyone is very pleased with our performance and quality of work. Thank you to all of the All Wall Employees that worked on this project to make it a success!

-Cody Luttrull

March 2023 Project Profile

Kootenai Health Heart Center Expansion

We are currently completing the EIFS (Exterior Insulated Finish System) at the $40 million expansion project at Kootenai Health in Coeur d’Alene Idaho, which includes 37,000 sf of an addition to the Heart Center including operating rooms and outpatient surgery, nine new patient rooms and multiple cardiac and heart rhythm disorder labs.

The areas for our work was divided into 3 separate building additions and multiple phases, starting with a mechanical penthouse (KOS Addition) on the roof directly over the Emergency Department entry, then moving over to another roof are for the OR (operating room) addition. Our last building area was the Heart Center addition and was divided into two phases, the North wall, and lastly the West wall and South soffit. The last area to complete will be a small infill of a temporary entry at the OR addition.

There were many challenges that our crew overcame, including having to work over a fully functioning hospital with very limited laydown area. The need to tent all our working areas and capture all foam particles from exiting and entering the hospital, along with managing work and materials next to an active helicopter pad. The project started in the Summer of 2022 and is now finishing in the winter of 2023 with working temperatures ranging from 0 degrees to 100 degrees.

The entire surface includes a two-coat base coat and mesh system utilizing Parex’s Hi-impact resistant basecoat and intermediate mesh. This is designed to prevent damage from any helicopter forced debris and bird nesting damage. Our total amount of wall and soffit surface is about 11,000 sf. It has been recognized by our Customer and GC partner, Bouten Construction as high quality looking product. They were very pleased with all our All Wall Contracting team, and the proactive approach we took throughout the project. Our team alerted Bouten to many issues early to assist them in meeting a very tight schedule.

This is a very important project for North Idaho and the growing population and the community. Our team did a beautiful project and was recognized for our professionalism and craftmanship. Great job and thanks to all of our Plastering crew that made this project a big success!

-Roy Glisson

February 2023 Project Profile

Spokane Tribe Casino

I’m really proud of this one y’all! Once again, All Wall had the privilege of performing the exterior and interior framing, exterior sheathing, interior hanging, taping, and ACT scopes of work on this phase of the Spokane Tribe Casino Expansion, which is a 61,600 square foot addition to the 12,240 square foot expansion All Wall did in 2021 for Swinerton Builders.

During the 2021 expansion we knew that the east exterior wall would be the entrance into what is now the non-smoking portion of the hotel, so with some careful planning all we have to do when we’re ready to open this phase to the public is remove some framing and drywall from the pre-framed openings. By doing this, it will allow the public into this new area with amazing ceiling features that we framed utilizing CWALLA’s “perfect curve” framing system. Another great addition to this casino is the Spokane Live concert and show venue that also prominently features the “perfect curve” framing system that greatly increases production and reduces the potential for flat spots in the soffits. Inside of Spokane Live there is over 3,000 feet of powder coated black fry reglet trim that will really set off the wallcovering being installed in that space. This phase of the casino also added a new admin area that will eliminate the need for the portable buildings, a new break area for the staff, training rooms, and a brand-new full kitchen that will serve employees and guests alike.

Thanks to our craftspeople and the dedication to their respective craft’s, along with the relationships we’ve built with the Spokane Tribe and Swinerton, we were just awarded the new 5-story hotel that will be attached to the west side of the casino. Great job everyone, and thank you so much for making this another successful project!

-Josh Menosky

January 2023 Project Profile

River City Urology

We are awaiting the final punch list for the River City Urology Clinic located on the 2nd floor of a brand new 2 story building in Post Falls where the Urology business is expanding from their current location in Coeur d’Alene. Currently, the 1st floor sits vacant with plans to have a Chiropractor lease part of the space and another 3,500 SF for a future tenant. We completed a number of scopes on this job for StanCraft Construction Group including metal stud framing, GWB hanging & taping, painting and high-impact wall covering. We also painted wall graphics and stained & sealed exposed glulam beams. We have now been asked to complete the intumescent coating on the above ceiling glulam beams. This has definitely been a challenging job with respect to schedule and sequencing but we made it to the end and the finished product is impressive. I want to thank everyone who worked on this job through the adversity and challenges to complete another quality project by All Wall.

-Scott Pinkerton

December 2022 Project Profile

Quality Stoves

Quality Stoves is a ground up building in Post falls. Some of you have probably driven past it and not even known, as it is right off the freeway. This building will be the new showroom and sales floor for quality stoves. We are completing this project for Baker and it has had its challenges. On this project we have completed the following scopes: frame, hang, tape, and paint. There has been a lot of added coordination with the GC and owners mostly due to the mock fire places that were framed out of steel studs throughout the showroom floor. There are 36 different fire places on the show room floor that all had to be framed to different elevations and sizes. We have done a great job navigating this challenging project as a team. I wanted to thank everyone who has been apart of this project for making it a success!

-Cody Luttrull

November 2022 Project Profile

Grocery Outlet Smelterville

Grocery Outlet in Smelterville is the third project we’ve done for out-of-town GC, RRC Contractors. All Wall, once again, performed the full exterior structural framing that bore the roof joists, thermal insulation with vapor barrier, exterior sheathing, interior drywall, taping, painting and stucco scopes of work. We then went on to work for another out-of-town GC on the interior build-out where we framed, insulated, hung, taped and painted all the interior walls and ceilings. It’s a real pleasure for me to see all our different disciplines come together to bring a building out of the ground and provide a great service to our clients, so a big thanks to everyone who put their sweat into this one!

-Joshua Menosky

October 2022 Project Profile

Rock Creek Clubhouse

The Rock Creek Clubhouse is a new Golf Course Club House for the Coeur d’Alene National Golf Course. This high end facility spared no expense and has exceeded $12 million dollars in construction cost to date. We teamed up with Baker construction on this one and were awarded the Painting, Wall Covering and FRP. Our Team has done an exceptional job on this, from OSPH and Paint at the exterior rusted steel, to installing the FRP throughout the bar area’s and Kitchen and hanging the VWC in the lockers and restrooms. We have and continue to receive high praise from Baker on our ability to finish our scopes in a timely manner and for continuing to pick up additional items that they have had trouble getting the others subs to complete. Great job on this one, TEAM! Keep up the good work.

-Joshua Williamson

September 2022 Project Profile

RIver Falls Apartments

With the ever-growing multi-family market in the Spokane – Coeur d’Alene area, we had an opportunity to partner with Baker Construction on the River Falls project. This project consisted of 5 buildings with 53 units and a rec room right here in Post Falls. As a team, we performed drywall hanging, taping and painting. River Falls brought new challenges as Baker had taken this project over from another contractor. Thanks to Travis Liles and our hanging crew, we were able to help Baker navigate through a partially completed job and get the project back on track. Both our crew leaders, Travis Liles and Chris Allen, did a stellar job! The communication and management between our leads was top notch and we couldn’t thank them enough. Thanks to all who made this project happen. With long hours and hard work, we can now step back and look at a job well done.

-Caleb Bradbury

August 2022 Project Profile

Kivalina K-12 School

We can see the finish line on the $43 million Kivalina K-12 Replacement School. This 38,000 sqft school is one-of-a-kind with its extravagant finishes and prominent design features. Not only will it be utilized for education, but it will also serve as the community’s emergency shelter in the event of a storm or flooding. We performed a variety of scopes including metal stud framing, drywall hanging & taping, painting, FRP, high impact wall coverings, ACT, Rulon wall panels and 3form plastic fabrications. Thanks to our crew leaders Rick Henjum & Charley Lane, along with the rest of the crew for battling through the realities of a harsh Alaska winter, flight delays, covid disruptions, lack of manpower, coordination conflicts, among many other hurdles. This is definitely one to be proud of as it showcases our skills in the various scopes we perform!

-Scott Pinkerton

July 2022 Project Profile

Idaho State Veterans Home

Idaho States Veterans Home will be a facility to house and care for our veterans. This facility is just a few blocks down from our office. Some of you have probably driven past it. Our scope for this project is installing an insulated cement board stucco system, a system we have not used before. There have been some learning curves for this new system but we were able to work our way through these. For this system we had a couple crews of hangers installing the insulated cement board ahead of the plasters following closely behind. Shawn Gonzales is our crew leader on this project and has done a fantastic job. As of early July we will be 99% complete with this project. I want to thank everyone that worked on this project to make it successful, and to turn over a wonderful product to the owner that will be such an important part of the community.

-Cody Luttrull

June 2022 Project Profile

Aloft Hotel

The Aloft Hotel is the first larger project that All Wall has taken on in the Anchorage area for some time. We have been completing smaller projects in the past couple of years, but none of this size. Our scopes were installing the RC-channel, hanging and taping/finishing of the GWB, along with the painting and wallcovering. The owners wanted to have an opening date of late May, which required a very fast-paced completion schedule. All Wall was aided by several Subcontractor for everything but painting. With so many people required, both All Wall employees and subcontractors alike, Greg Shull’s overall Supervision was invaluable. He had to spend most days managing and moving people around to get them to the hot spots that popped up quite regularly on this project. I want to personally thank the Subcontractors Vulcan Dry Wall, Prime Time Drywall, Joe Paul Pierre and the All Wall staff that worked 7 days a week so that the hotel could meet the opening date. Now we can move on to bigger and better projects. Great job by all, from the estimating team to the painters who finalized the last of the punch list.

-Terry Jones

May 2022 Project Profile

RDO Equipment

Another successful full scope project by the All Wall team in the books! RDO is a farming equipment supplier in Moses Lake. The client, an out-of-town GC from Wisconsin, saw the value in our systems and awarded us the framing, hanging, taping, painting, ACT, and EIFS scopes of work. This project had some unique challenges that created opportunities for our teams to really come together and transition from one trade to the next better than could’ve possibly happened if the GC needed to engage as many as 4 subcontractors to complete what we did as 1 sub. Which proves yet again that you guys are the best around. I’d also like to give a special shoutout to Shawn Stilson for excellent leadership on this one. Thanks Shawn!

-Joshua Menosky

April 2022 Project Profile

Lake City Church

The Lake City Church Remodel project is located off of Ramsey Road in Coeur d’Alene. We were tasked with remodeling two different areas: the new children’s classrooms and toddler room, and the new offices for the church. This project provided us the opportunity to perform almost all of our scopes. We began by framing and hanging new partitions, then we taped and painted the new and existing walls, stained and finished doors and trim, painted the existing ACT in the lobby and hallway, and finally installed ACT in the new rooms. The All Wall field crews have done a great job to turn over a high quality product to the client. Thank you to everyone involved with this project for their hard work and to make it a success.

-Cody Luttrull

March 2022 Project Profile

River Falls

River Falls is a new 5 building apartment complex in Post Falls on Railroad Ave. Travis and crew have been running hard on the prerock, their great attitude and performance have been appreciated by the GC as they work through less than ideal conditions. We have been a big help completing our work and picking up other loose ends to keep the train rolling.

-Michael Hauschild

February 2022 Project Profile

Coeur d’Alene Casino

I5 Design, based out of Lacey, Washington is a design build firm that specializes in casinos all across North America. I5 hired us to create a VIP Gaming Lounge for the Coeur d’Alene Casino in Worley. We framed several radiused walls and soffits with a level 5 finish, most of which received high-end digital wallcovering we installed, a detailed trim package (installed by others) that was painted or stained in our shop, as well as colored acoustical ceilings.

I5 was so happy with All Wall, and they had enough faith that we could continue to deliver, that they allowed us to take the reins on the VIP Food Court (which is adjacent to the VIP Lounge) with only concept drawings. True to our word, and consistent with our high standards, we turned it into a space ready for wallcovering and ceiling elements prior to the finished drawings even being issued.

Once again, the All Wall field crews made me very proud to be a part of this team. But most importantly, I5 has gone from a customer that’s never worked with us before, to becoming a client that will continue to utilize our services on all of their casino projects within All Wall’s regular market.

-Joshua Menosky

January 2022 Project Profile

6th & Browne

A full remodel of an existing medical facility, 6th & Browne, has signaled the change in landscape for the Spokane area. The 3-Story Concrete building was converted into 27 high-end apartments, with a touch on modern aesthetics.

Our Scopes on this project were, Acoustic and Thermal Insulation, Interior Framing, Taping and Painting of the interior and exterior of the building. This project was completed with a joint effort from all of our scopes.

The interior of the units features exposed concrete beams that presented quite a challenge due to their sagging over time. The exterior of the building is a combination of CMU, Pre-Cast, and newly installed Hardie panels where concrete had to be removed at the 1st floor line.

I would like to give a big Thank You to each and every crew member who chipped in to see this project through to completion.

-Joshua Williamson

December 2021 Project Profile

Riverstone Apartments

Our Riverstone Apartments project is finally wrapping up after almost a year of work as we hang our last sheets of drywall this month, with tapers and painters not far behind. All Wall Contracting took on the metal frame, drywall, tape, paint, ACT, and FRP scopes for this project, all of which should be near complete by 2022. Named “The Timbers,” this 62 unit apartment building near downtown Coeur d’Alene has challenged us with a very unique sound-isolation design, demanding turnover schedule, and custom home level of design all during a labor shortage and global pandemic. Despite this job’s challenges, crew lead Josh Kirk has done an awesome job of managing a crew of up to 60 employees and subcontractors, as well as coordinating all of the detail work, such as its metal-framed fireplaces and elevator fronts. This job marks another strong step for All Wall into the growing multi-family housing market in the Coeur d’Alene/Spokane area.

Residents are set to move into the 3rd and 4th floors in mid-December, so there has been a big push the last few months to finish our scopes without sacrificing quality. I’m happy to say that our employees and subs have worked hard to pull this off.

-Connor Jacobs

November 2021 Project Profile

JBER AK USPFO Building

JBER AK USPFO Building started in Oct of 2020 and was originally scheduled to be completed May 2021. However, with windows being delayed by6 months, pushing the entire project behind schedule, we are now just finishing up the project. This project was quite the struggle. First there was the battle to heat a building during an Alaska winter without windows. Then we also had to deal with the Covid factor. In spite of all the challenges, we have managed to push through and now we are finally seeing the end. The project consists of2 buildings: one unheated vehicle storage and the other is a half warehouse / half administration. We were responsible for performing taping, painting, EIFS, wallcoverings. Thank you to all who worked and struggled through this project with me to make it a success.

-Greg Shull

October 2021 Project Profile

Caravel Autism Health Clinic

Caravel Autism Health Clinic located in North Spokane was a great showcase of All Wall’s skill in the framing, drywall, and paint scopes of work. We did this project with an out-of-town GC who really depended on us to help guide their inexperienced field team through this project, and to deliver on a very tight schedule. The major architectural highlight of this project was the “wave wall” featuring 3 different shades of blue, painted by Amber World and her team. This project holds a special place in my heart, as I know firsthand how important it is for a parent to find a place where their special needs child is respected, understood, and the parents are listened to. Thanks to all of the field workers who made this project such a great success!

-Joshua Menosky

September 2021 Project Profile

Barrow Airport Maintenance and Operation’s Facility

Barrow Airport Maintenance and Operation’s facility is finally underway after many months of preparation. Barrow, Alaska is in the very remote northern point of the state, and due to this there is months of preparation that goes into bush projects like this one. All of the non-perishable materials, ie. metal studs and board are already there onsite for the whole project by the time our workers first arrive. This preparation began months ago with getting the materials delivered to the barge that leaves from Seattle, WA, and takes 2-3 months to reach the project location. On this particular project we are performing the following scopes: Framing, Hanging, Taping, Painting, ACT, & FRP. We are currently framing and have started to hang some of the board. Roscoe Davenport is our crew leader on this project and has been doing a great job. We are working with SKW on this project, and we are projected to be completed by Spring of 2022.

-Cody Luttrell

August 2021 Project Profile

Family Dollar

The Family Dollar in Oldtown originally started as a shell only, which was awarded to us by a repeat customer from out of town, because they knew All Wall could be counted on to provide them with excellent service and quality construction. It then turned into the tenant improvement side of the Family Dollar as well, because the owners liked the work that our customer was turning over to them (All Wall’s work). This project had a rough start when the exterior walls that were only about 1/3 framed got blown down when a microburst of wind came through the valley in Oldtown. We got the wall back up and thankfully no one was hurt. Now that the exterior stucco and EIFS will be completed in the next 2 weeks; the drywall has been hung on the inside of the exterior walls; the interior walls and ceilings are framed, with drywall starting right around the corner, the tapers and painters are hot on their heels. With the hard work of our field teams, we were able to dig ourselves out of the hole the destruction created, and are on our way to the completion of another successful and profitable project!

-Josh Menosky

July 2021 Project Profile

Project Fireball

Our crews have been doing a great job at Project Fireball. Several breakrooms, mechanical rooms, and a large office area have spread us across the nearly 25-acre footprint. Our work started in March and turnover is scheduled for end of July. The jobsite has been very busy and all our crews there have been very good at working through the chaos. Thank you to all who have worked OT and put in extra effort to help us make the ambitious schedule!

-Michael Hauschild

June 2021 Project Profile

Stancraft Jet Center

We have recently completed the work on this 30,000 SF hanger and luxury jet Center located in Hayden, Idaho. The project was is comprised of 3 buildings- the Jet Hanger, the upholstery/maintenance shop, and the office/ lounge facility. We completed the Steel Stud framing, exterior sheathing, GWB and painting of the Hanger Building’s fire rated wall assemblies. This included multiple 3 hour and 2 hour rated wall assemblies that were complicated by installing these around a Metal building package.

The Upholstery Building work included a large overhead GWB ceiling and GWB & OSB painted walls installed over a wood framed structure, with exposed stained wood beams and painted steel columns.

The luxurious Lounge and Office building includes a Thomas Hammer Coffee Café, a Crew lounge with a Golf simulator, sleeping and showering quarters for the pilots and crews, a StanCraft wooden Boat display, a conference room, offices and many other amenities. It is designed and built to service the Jet set families that frequent North Idaho for the world class summer and winter recreation.

Our work involved installing the GWB/Fry Reglet with an imperfect smooth texture over wood framing, staining of the interior and exterior reclaimed wood ceilings/siding and exposed wood beam, Painting of the walls, metal doors, frames and exposed steel beams, installation of the FRP and vinyl wallcoverings.

This was a difficult project that took the All Wall Contracting’s crews 13 months and over 12,400 hours to complete. It was a demanding intense project with a high-end customer, and completed entirely through the COVID 19 pandemic.

With all the delays of design issues, materials delays and labor shortages it was over 7 months behind schedule but it is a one-of-a-kind type facility for our region and one that we should all be proud of. With our dedicated team of crew leaders, framers, hangers, tapers, painters, wallcovering installers and superintendents this was a successful project. Kudos to all that worked so diligently for so long to make this project a reality.

-Roy Glisson

May 2021 Project Profile

Spokane International Academy Phase 2

Spokane International Academy Phase 2 is a near total remodel of the first and third floors with a little work on the second, of a K-8th grade charter school focusing on high academic standards in north Spokane. This project has an incredibly aggressive schedule, and is one of those projects where All Wall is able to shine, and show our customers (TW Clark in this case) that utilizing us for the full framing, hanging, taping, painting and ACT scopes will allow this project to be brought in on time and under budget. We do this by scheduling and overlapping all of those scopes internally instead of the GC having to struggle to bring all of those scopes together in the proper sequence and timing. One thing we are doing that will help is beginning topout almost as soon as the full height walls are framed. Close coordination with the HVAC contractor and getting the GC to buy-in and partner with our method up front was key in allowing this to happen. Since we have 9’ ceilings throughout on this project, we have special ordered 10’ lightweight board that we will stand up instead of laying it down. This achieves two things; first as our hangers are standing the board up at 10’ they are immediately getting into “topout” production with that 1’ of board above the ceiling height. Secondly, by standing the board up we will have eliminated butt joints that the tapers would have had to tape, and thereby increase their production by approximately 15-20%. And finally, we traditionally succeed when we can be the driving force on a job by pushing the MEP trades and never having to pull off or slow down. Looking forward to seeing the end result and completing another successful project with this All Wall team!

-Joshua Menosky

April 2021 Project Profile

Spokane County Mental Health Crisis Stabilization Facility

We are close to the finish line on the 19,000 SF Mental Health Crisis Stabilization Facility in Downtown Spokane. This facility will be the first of its kind in the Spokane area with the goal of helping people with mental illnesses and substance abuse issues avoid unnecessary jail time. The stabilization facility will be equipped with mental health professionals, medications, places to sleep and a safe atmosphere. We are performing the metal stud framing, drywall hanging and taping and EIFS work for Baker Construction who continues to award us more of their work. We have managed to stay on schedule even with the additional change order work and various coordination conflicts. Thank you, team, for helping make this another successful project for All Wall!

-Scott Pinkerton

March 2021 Project Profile

University of Idaho Central Credit Union Basketball Arena. We were awarded this project last year for Painting and things are really starting to pick up with interior finishes. As well as interior and exterior painting, we will also be power washing and sealing over 77,000 sq./ft. of concrete floor. On the exterior of the project, we will be applying a High-Performance Coating to the steel and graffiti and Water Repellents to multiple areas of CMU. When all is said and done, we will use over 2,750 Gallons of Painting/Staining product on this project, WOW! The arena has massive curved Glu-Lam Beams and is one of a kind in the area with this architectural feature. There is a live stream of the Project on uidaho.edu website and a time-lapse from 08/08/2019 to present. We appreciate everyone’s efforts on this one and look forward to finishing this project strong in the late summer.

University of Idaho Central Credit Union Basketball Arena. We were awarded this project last year for Painting and things are really starting to pick up with interior finishes. As well as interior and exterior painting, we will also be power washing and sealing over 77,000 sq./ft. of concrete floor. On the exterior of the project, we will be applying a High-Performance Coating to the steel and graffiti and Water Repellents to multiple areas of CMU. When all is said and done, we will use over 2,750 Gallons of Painting/Staining product on this project, WOW! The arena has massive curved Glu-Lam Beams and is one of a kind in the area with this architectural feature. There is a live stream of the Project on uidaho.edu website and a time-lapse from 08/08/2019 to present. We appreciate everyone’s efforts on this one and look forward to finishing this project strong in the late summer.

-Joshua Williamson

February 2021 Project Profile

This project is one we were just awarded the Exterior Shaftwall assembly that gets installed to create a fire barrier between the existing building and where the relocated building meet. The assembly requires peel and Stick Air and Moisture barrier, shaft liner, 3.5” insulation, a layer of dens-glass gold and finally and another layer of peel and stick air and moister barrier. Along with this work, we also were awarded the interior ceiling framing, Taping, Painting. Wall Protection and the ACT. The beauty of this project is that it starts in Late February and will fill a void in our schedule. I am working on the General Contractor to give us a change order to hang the interior GWB and install the sound batt insulation. Hold on to your hats as it is going to get busy in the Greatland !

This project is one we were just awarded the Exterior Shaftwall assembly that gets installed to create a fire barrier between the existing building and where the relocated building meet. The assembly requires peel and Stick Air and Moisture barrier, shaft liner, 3.5” insulation, a layer of dens-glass gold and finally and another layer of peel and stick air and moister barrier. Along with this work, we also were awarded the interior ceiling framing, Taping, Painting. Wall Protection and the ACT. The beauty of this project is that it starts in Late February and will fill a void in our schedule. I am working on the General Contractor to give us a change order to hang the interior GWB and install the sound batt insulation. Hold on to your hats as it is going to get busy in the Greatland !

-Terry Jones

January 2021 Project Profile

Empire Eye may look familiar to some of you, as you drive down I-90 you can see it right against the north side of the freeway near Sullivan. Ginno spent the fall getting structure up and is now ready for us to come in with Drywall, Mud, Paint, and Wallcovering. Ginno has done a great job of keeping the building clean and organized, let’s make sure we keep that up and deliver another quality project we can all be proud of to one of our best customers.

Empire Eye may look familiar to some of you, as you drive down I-90 you can see it right against the north side of the freeway near Sullivan. Ginno spent the fall getting structure up and is now ready for us to come in with Drywall, Mud, Paint, and Wallcovering. Ginno has done a great job of keeping the building clean and organized, let’s make sure we keep that up and deliver another quality project we can all be proud of to one of our best customers.

-Michael Hauschild

December 2020 Project Profile

Exterior framing has begun on the SafeSplash/SwimLaps project in Coeur d’Alene, and is moving along nicely. This is an indoor swimming facility where young people can go to learn to swim in a safe and indoor environment. There will be one full size pool and two kiddie pools with a viewing area for parents to watch their children learn to swim.

We are performing the exterior framing, which in conjunction with the structural steel, will support the roof structure. Due to cold weather restrictions and to eliminate tenting and heating costs, we are utilizing GP’s DensElement sheathing which has an integrated weather barrier. From there our scope moves on to interior framing, thermal and acoustical insulation, drywall, drywall finishing and painting. This is another opportunity for All Wall to showcase to our customers what an all-encompassing package can do to not only reduce their costs, but also reduce callbacks, increase efficiency with improved coordination, and help with their overall schedule. I look forward to the completion of this project and the positive impact it’ll have on the community. Maybe your children will learn to swim there too!

We are performing the exterior framing, which in conjunction with the structural steel, will support the roof structure. Due to cold weather restrictions and to eliminate tenting and heating costs, we are utilizing GP’s DensElement sheathing which has an integrated weather barrier. From there our scope moves on to interior framing, thermal and acoustical insulation, drywall, drywall finishing and painting. This is another opportunity for All Wall to showcase to our customers what an all-encompassing package can do to not only reduce their costs, but also reduce callbacks, increase efficiency with improved coordination, and help with their overall schedule. I look forward to the completion of this project and the positive impact it’ll have on the community. Maybe your children will learn to swim there too!

-Josh Menosky

November 2020 Project Profile

November 2020 Project Profile

It is a race to the finish line on the 43,000 square-foot, 92 guestroom Tru Hilton Hotel in the Spokane Valley as it is set to open before the fast approaching holidays. The General Contractor, Maurer Construction, has relied on us heavily throughout the project to push the aggressive schedule due to our large scope of work which includes metal stud ceiling & soffit framing, GWB hanging, taping & texturing, acoustical ceilings, painting, wallcovering & EIFS. Our successful completion of this project is crucial to potential future work as the owner has plans for another hotel next door to this one. Thank you to everyone who has put in the extra effort to drive this project home!

–Scott Pinkerton

October 2020 Project Profile

Verizon Tech Center: This project is a large exterior repaint of a building in downtown Spokane which the owner wanted to make sure we completed this year. We will pressure wash to remove loose dirt and paint and apply one coat of Sherwin Williams Conflex Sherlastic at 10 mils thick to the body. We will use the same product to stripe all the hairline cracks in the building. There is also a large set of metal balconies that will have to be cleaned, primed and coated. Robert Eastwood is the lead on this project.

-Brian McAnnally

September 2020 Project Profile

Iron Bridge Condos Roof Coatings: This job is located right on the Spokane River. We did 1.5” spray foam over PVC to raise R value and 4” spray foam over EPDM roof to raise R value to meet code. Without this spray foam installation, the alternative would have been to tear the roof off and start over. We also installed new gravel stop flashing all along the west edge of the roof so that we had a termination point for the foam install. We washed and primed the entire roof prior to foam installation which was subcontracted to Dodge Foam and Coatings. After the foam went down, we applied 2 separate coats of silicone at a rate of 1.25 gallons per square per

coat for a total yield of 2.5 gallons per square. We used a secondary product called Seam Seal to detail at all penetrations and foam termination points. There are roughly 450 gallons of silicone installed. This project was done with Divcon Construction and took ap

prox. 3 weeks to complete between the foam and coatings installation.

-Karl Aldrich

August 2020 Project Profile

August 2020 Project Profile

Phase 2 of Tuntutuliak in Alaska has kicked off this month for All Wall crews. We are back on the roof installing Z-furring and plywood. On the ground we are painting pilings and structure under the building. Our crews are working hard to get the building dried in so work can continue inside this winter. Extra testing and precautions are being taken when flying into the village and living on the jobsite to reduce the risk of COVID spreading to the population. Thank you all for respecting the community by cooperating and following these measures for the health of this community we serve.

-Michael Hauschild

July 2020 Project Profile

July 2020 Project Profile

While the Dollar Tree in Smelterville, Idaho is a small project, it touches most of our scopes of work and highlights why All Wall is the go-to subcontractor for many GC’s that we’ve built a relationship with over the years, and those who work with us for the first time.

This 10,000 square foot free-standing building is built with our studs supporting the roof joists and roof, utilizing bearing stud-packs at each joist and support blocking at the roof line for the deck angle. With radius dimensions from the plans, we had CWALLA pre-bend track to make installation of the arched entryway on the southern face of the building an easy and clean install. That same southern face will be receiving a stucco/EIFS finish, with pre-formed arched cornice pieces at the entry, and pre-formed cornice pieces at the columns as well. Once the stucco/EIFS is completed, our paint crew will be painting the top EIFS band and metal parapet cap. About the time the above-mentioned work is completed, we will have insulated and hung the interior side of the exterior walls, finished them to a level 4, and be ready for paint. As all we are providing is a shell for the owner, we won’t be installing any interior walls or acoustical ceilings, so once we’ve painted the interior walls to 12’ we walk out the door and on to the next one…

–Joshua Menosky

June 2020 Project Profile

The New Health Sciences Project is officially underway. This project is located on Central Washington University’s Campus in Ellensburg, Washington. This state of the art 81,000 square foot facility will house the schools Clinical Physiology, Nutrition, Paramedicine, Public Health Programs, and Exercise Sciences. We are preforming heavy gauge exterior metal framing, light gauge interior metal framing, and drywall hanging and taping. The exterior framing isn’t a typical framing system with the wall being framed from the top of the windowsill to top of the windowsill instead of floor line to floor line. Due to this we are panelizing parts of the exterior framing for the job at our shop in Post Falls, Idaho. Roscoe Davenport is the Crew Lead on this job and is working closely with T.W. Clark’s Superintendent to make this project a great success. We are working hard to get the exterior of this massive building closed up before winter hits. The completion of our scopes is anticipated to be end of the year 2021.

-By Cody Luttrull

May 2020 Project Profile

This Project is a new building at the Kootenai County Ramsey Transfer Station for handling hazardous household waste.Our scopes are framing, drywall, plywood wainscot, painting and resinous flooring. The floor coating was outside of what we normally do in that it was a 1/8” Moisture Vapor Transmission (MVT) basecoat with 2 different topcoats of Novolac epoxy. The MVT coating allows water vapor to escape through the floor and provides impact resistance while the Novolac epoxies provide protection against a variety of chemicals.

-By Brian McAnnally

March 2020 Project Profile

March 2020 Project Profile

The Welding Shop Consolidation project is officially underway after multiple project delays due to government suspensions. This high security project is located on the Hawaiian Island of Oahu at the Joint Base Pearl Harbor-Hickam naval shipyard and is part of our nation’s largest, most comprehensive fleet repair and maintenance facility between the U.S. West Coast and the Far East. The students and workers at the Weld Shop help to provide a capable, ready and “Fit to Fight” fleet by repairing, maintaining and modernizing the U.S. Pacific fleet. We are performing heavy gauge metal stud framing, drywall hanging and ACT scopes on the new office and classroom portions of the job. Tyler Brady is our Crew Leader on site and has been doing a great job working closely with Bethel Contracting’s Superintendent to help make this project a success. Completion of our scopes is anticipated to be in June of 2020.

-Scott Pinkerton, Project Manager

February 2020 Project Profile

The finish line is in sight at Triton Mission Control. By mid-February, drywall and painting will be complete and ACT ceilings well underway. Now is the time to run hard to the finish line and keep the good momentum we have going. It has been our team’s ability to meet the schedule and manpower demands that has made this project successful. Bethel-Webcor JV has been our customer and will be again this summer when we start the P-253 Fleet Control project. We look forward to finishing Triton strong and carrying the success into P-253. A BIG Thank You to everyone who made the trek to Whidbey and helped to deliver another quality project!

-Michael Hauschild, Project Manager

January 2020 Project Profile

At Home is a large home décor store that is gradually expanding into the Northwest, each store has a footprint of 80,000SF. Work is currently underway on our fourth At Home project with Parkway Construction out of Texas, with our scope of work being Paint and ACT. The At Home stores that we have painted average 1800 gallons of paint and usually take 2-3 months. This particular store is being fast tracked and will be done in under 2 months. A major feature of these projects is the large exposed ceilings that take 1200 gallons of flat white dryfall (paint that dries as it falls). Dave Barringer is the lead on his second store that is scheduled to open Feb 6, 2020.

-Brian McAnnally, Project Manager

December 2019 Project Profile

December 2019 Project Profile

Wiggett Building, named after James Wiggett a early developer and merchant in Coeur d’Alene, is a 27,000sf 3 Story Building on the corner of 4th & Lakeside in Coeur d’Alene just a couple of blocks from the One Lakeside Project. The building was originally a Montgomery Wards that was built in the 1920’s but sat empty for over 10 years prior to its renovation. The building is a mixed use building with office spaces occupied by Welch Comer Engineers, The Murray Group and Widmyer Corporation and retail spaces with a Woops café and hot yoga studio. All Wall worked directly for the Owner and alongside LaRiviere Contracting and performed many scopes including drywall hanging & taping, painting, blown-in insulation and ACT. The bulk of our work is complete but we continue to work on retail space tenant improvements when the Owners rent new spaces.

-Gene Rohrs, Project Manager

Photo of the Month

July 2024

Photo Credit: Jeffrey Amsden

McEuen Terraces Eastside EIFS Refinish, Couer d’Alene, ID

June 2024

Photo Credit: Hammond Bradford

Children and Youth Services Center – Spokane, WA

May 2024

Photo Credit: Jeffrey Davis

NWSH MRI-CT – Post Falls, ID

April 2024

Photo Credit: Phil Evans

Grand Coulee Fire Station – Grand Coulee, WA

March 2024

Photo Credit: Hammond Bradford

Sravasti Abbey Buddha Hall – Newport, WA

February 2024

Photo Credit: Tim Gronwold

PMRA Terminal Project – Pullman, WA

January 2024

Photo Credit: Tyler Wilson

YKHC Qavartarvik Customer Lodging – Bethel, AK

December 2023

Photo Credit: Rick Henjum

STEP Phase 3 Hotel – Airway Heights, WA

November 2023

Photo Credit: Taylor Batchelder

Spokane Industrial Park Roofs – Spokane Valley, WA

October 2023

Photo Credit: Austin Malmoe

Nutex Post Falls Emergency Hospital – Post Falls, ID

September 2023

Photo Credit: Jacob Altieri

Pointe at Post Falls – Post Falls, ID

August 2023

Photo Credit: Jacob Eleazer

Kindred & Co. Bookstore and Bistro – Post Falls, ID

July 2023

Photo Credit: Tim Gronwold

HZCU Facilities Building – Spokane, WA

June 2023

Photo Credit: Justin Eastwood

Goodwill West Plains – Airway Heights, WA

May 2023

Photo Credit: Jesse Pierce

Torrey Pines – Riverview Assisted Living Facility – Juneau, AK

April 2023

Photo Credit: Austin Malmoe

Kindred Bookstore and Bistro – Post Falls, ID

March 2023

Photo Credit: Tom Larson

Kootenai Health Heart Center Expansion – Coeur d’Alene, ID

February 2023

Photo Credit: Alex Woracker

Goodwill – West Plains, Spokane, WA

January 2023

Photo Credit: Richard Henjum

Spokane Tribe Casino – Spokane, WA

December 2022

Photo Credit: Jimmie Connell

YKHC Qavartarvik Customer Lodging – Bethel, AK

November 2022

Photo Credit: Phil Evans

Goodwill – West Plains – Spokane, WA

October 2022

Photo Credit: Hammond Bradford

Quality Stoves – Post Falls, ID

September 2022

Photo Credit: Isaiah Alexander

Spokane Industrial Park – Spokane Valley, WA

August 2022

Photo Credit: Frank Schnabel

Dave Smith Motors Jeep – Kellogg, ID

July 2022

Photo Credit: Rick Henjum

Kivalina K-12 School – Kivalina, AK

June 2022

Photo Credit: Austin Malmoe

Grocery Outlet – Smelterville, ID

May 2022

Photo Credit: Shawn Gonzalez

Idaho State Vet Home

April 2022

Photo Credit: Jesse Pierce

Mt Stuart Elementary

March 2022

Photo Credit: Rick Henjum

Kivalina K-12

February 2022

Photo Credit: Shawn Gonzales

Idaho State Veterans Home

January 2022

Photo Credit: Dave Hartman

CWU Health Sciences Building

December 2021

Photo Credit: Scott Pinkerton

Idaho State Vet Home

November 2021

Photo Credit: Matt Fox

Child Hunger Solution Center

October 2021

Photo Credit: Tim Gronwold

University of Idaho Central Credit Union Arena

September 2021

Photo Credit: Jessie Pierce

Ridgeline High School

August 2021

Photo Credit: Josh Menosky

SafeSplash Swim Lab

July 2021

Photo Credit: Rick Henjum

Spokane Tribe Casino

June 2021

Photo Credit: Roy Glisson

Stancraft Jet Center

May 2021

Photo Credit: Shawn Gonzales

CBHA Connell

April 2021

Photo Credit: Joshua Menosky

One Lakeside

March 2021

Photo Credit: Todd Patterson & Rick Henjum

Spokane Tribe Casino

February 2021

Photo Credit: Nick Cooper

Stancraft Jet Center, Hayden, ID

January 2021

Photo Credit: Shawn Gonzales

Tru Hotel, Spokane Valley, WA

December 2020

Photo Credit: Dale Phillips

Building #32 at the VA Hospital, Spokane, WA

November 2020

Photo Credit: Tyler Brady

Barrow High School, Barrow, Alaska

October 2020

Photo Credit: Shawn Gonzales

One Lakeside – Coeur d’Alene, Idaho

September 2020

Photo Credit: Roscoe Davenport

CWU Health Sciences in Ellensburg, WA

August 2020

Photo Credit: Frank Schnabel

One Lakeside in CDA, Idaho

July 2020

Bethel Hospital

June 2020

Photo Credit: Jeffrey Davis

Whatcom County Courthouse EIFS

May 2020

Photo Credit: Jacob Eleazer

Foxtail Elementary Cloud Soffit

April 2020

Photo of Bethel Hospital in Alaska from our Archives!

March 2020

Photo Credit: Josh Silba

Before and After Painting of Delta Fuel in Alaska

February 2020

Photo Credit: Ron Lowery

The Watts Signage Painting

January 2020

Photo Credit: Steven Miller

Project Rose (Amazon Dist. Center)

December 2019

Photo Credit: Travis Liles

Spokane Housing Authority